Partnership uses F1 engineering to create carbon fibre reinforcement that increases the stiffness of the classic 911 by 175%

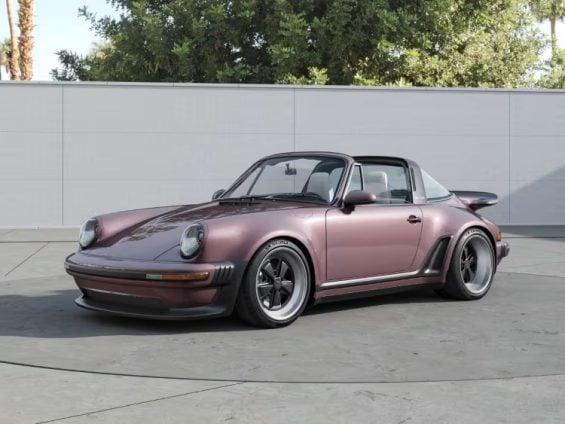

Singer Vehicle Design, a renowned classic car restorer, turned to Red Bull Advanced Technologies to solve a chronic shortcoming of the Porsche 911 convertible models: low torsional rigidity. Through the use of engineering applied to Formula 1, the partnership managed to transform the driving dynamics of the Cabriolet and Targa versions of the 964 generation, historically hampered by the absence of a fixed roof.

In vehicles without the upper structure, the connection between the front and rear axles is compromised, resulting in a chassis susceptible to excessive twisting during curves or on uneven pavement — a phenomenon known in engineering as scuttle shake. To mitigate this behavior without detracting from the vehicle’s character, the technology of the tracks was fundamental.

SEE ALSO:

Red Bull’s response to the structural dilemma was the development of a kit composed of 13 carbon fiber parts, designed to strengthen the chassis’ nerve points without altering the car’s original architecture. The practical result was a significant increase of 175% in torsional stiffness. The great merit of the project, however, lies in the weight-power ratio: the structural reinforcement was obtained with an irrelevant mass increase, preserving the agility that consecrated the models restored by Singer.

With the stabilized structure, the vehicle’s dynamics change radically. The load generated in sudden maneuvers is no longer dissipated by the deformation of the body and is now correctly absorbed by the suspension assembly and tires. According to Red Bull, this change allows convertible models to offer, for the first time, a steering precision and braking efficiency equivalent to those of hardtop coupes, eliminating the “dynamic chasm” that existed between the configurations.