In partnership with Boston Dynamics, the automaker invests in 'physical AI' and expects annual production of 30 thousand units of the robot for industrial tasks.

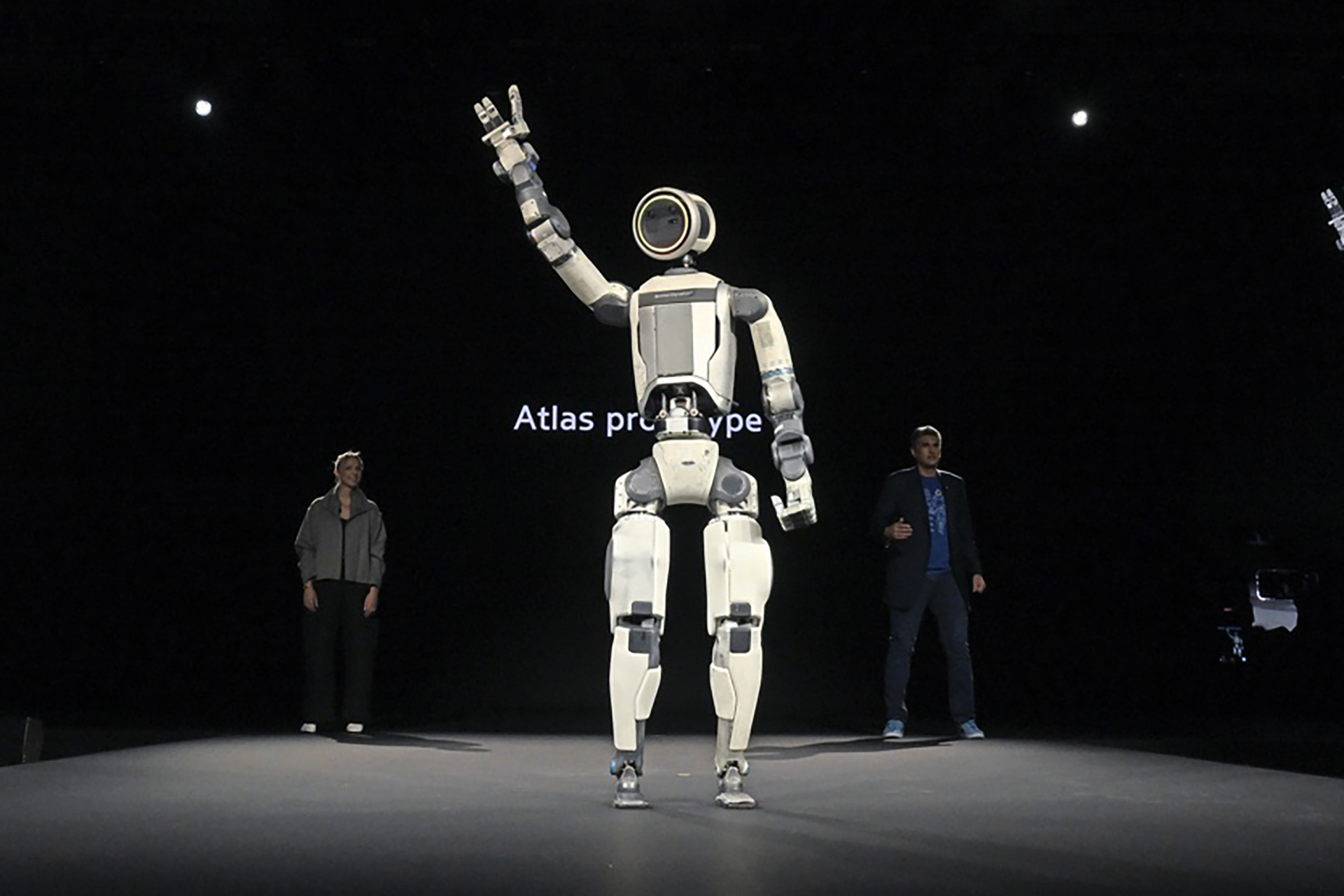

Hyundai has made official the transition from humanoid robots in laboratories to ‘manual work’ in the automobile industry. During CES 2026, the automaker announced that the final version of the Atlas robot, developed in partnership with Boston Dynamics, will begin commercial work in its factories in the United States starting in 2028.

The move ushers in what the company classifies as the era of “physical AI”. Unlike previous prototypes, famous for parkour videos on the internet, the new Atlas was designed with a strictly industrial focus: it is a robust machine, capable of operating in temperatures ranging from -20 °C to 40 °C and handling loads of up to 50 kilograms — including irregular parts that conventional robots cannot hold.

SEE ALSO:

The introduction of the Atlas on the production line will follow a staggered schedule. In 2028, robots will take over logistics, sequencing and parts organization functions. The projection is that, from 2030 onwards, they will start to perform complex tasks directly in the assembly of vehicles.

To make this autonomy possible, Hyundai has partnered with Nvidia. Atlas will use physical intelligence clusters based on Blackwell GPUs, allowing the machine to learn and adapt in real time to variations in the factory environment, without the need for constant reprogramming for each new movement.

The bet on robotics is structural: Hyundai plans to invest US$ 26 billion (approximately R$ 138.6 billion) in its operations in the US by 2028, in infrastructure that will support the ambitious goal of producing 30 thousand units of the Atlas per year.

According to the automaker, the goal of advanced automation is not only efficiency, but the reduction of human risks in unhealthy and dangerous tasks. The new robot’s 360° rotating joints allow for movements that surpass human flexibility, ensuring continuous operation in confined spaces.